ABC-BioPhosphate is a Bone Char is a unique from of activated carbon, made of food grade animal bone meal and it’s ability to remove many PTE (Potential Toxic Elements ) and macromolecular organic contaminants is far greater than coal or coconut shell based activated carbon.

Animal bone char is an effective adsorbent for water filtration, as it ability to remove many metals and macromolecular organic contaminants is far greater than activated carbon. Most of these metals are neurotoxins and pose significant hazards to human health.

ABC-BioPhosphate Green Adsorbent – Advanced Water Purification for a Cleaner, Safer Future

ABC-BioPhosphate is a high-performance, bio-based green adsorbent, engineered to effectively reduce and remove a broad spectrum of contaminants from water and other liquid media. Its unique macro-porous structure and optimized surface chemistry ensure exceptional adsorption efficiency, making it an ideal solution for industrial-scale, municipal, household, and defence applications.

It effectively removes pollutants such as fluoride, cadmium, lead, iron, manganese, mercury, zinc, copper, nickel, aluminum, arsenic, herbicides, pesticides, and radionuclides including radium and uranium.

In tap water purification, ABC-BioPhosphate eliminates harmful toxins while preserving essential salts and beneficial minerals, ensuring safe, great-tasting water. It is also widely applied in industrial water treatment and sugar refining, where it removes mineral impurities and decolorizes without affecting product quality.

Beyond civil and industrial use, ABC-BioPhosphate also supports defence and security operations, including chemical, biological, and radiological hazard mitigation—providing safe, chemical-free decontamination in critical environments.

From municipal water treatment plants to industrial wastewater management, household filters, and defence applications, ABC-BioPhosphate offers an environmentally friendly, chemical-free, and highly efficient solution for clean water, safe soils, and hazard protection.

Why Choose ABC-BioPhosphate Adsorbents?

Prevent. Protect. Recover.

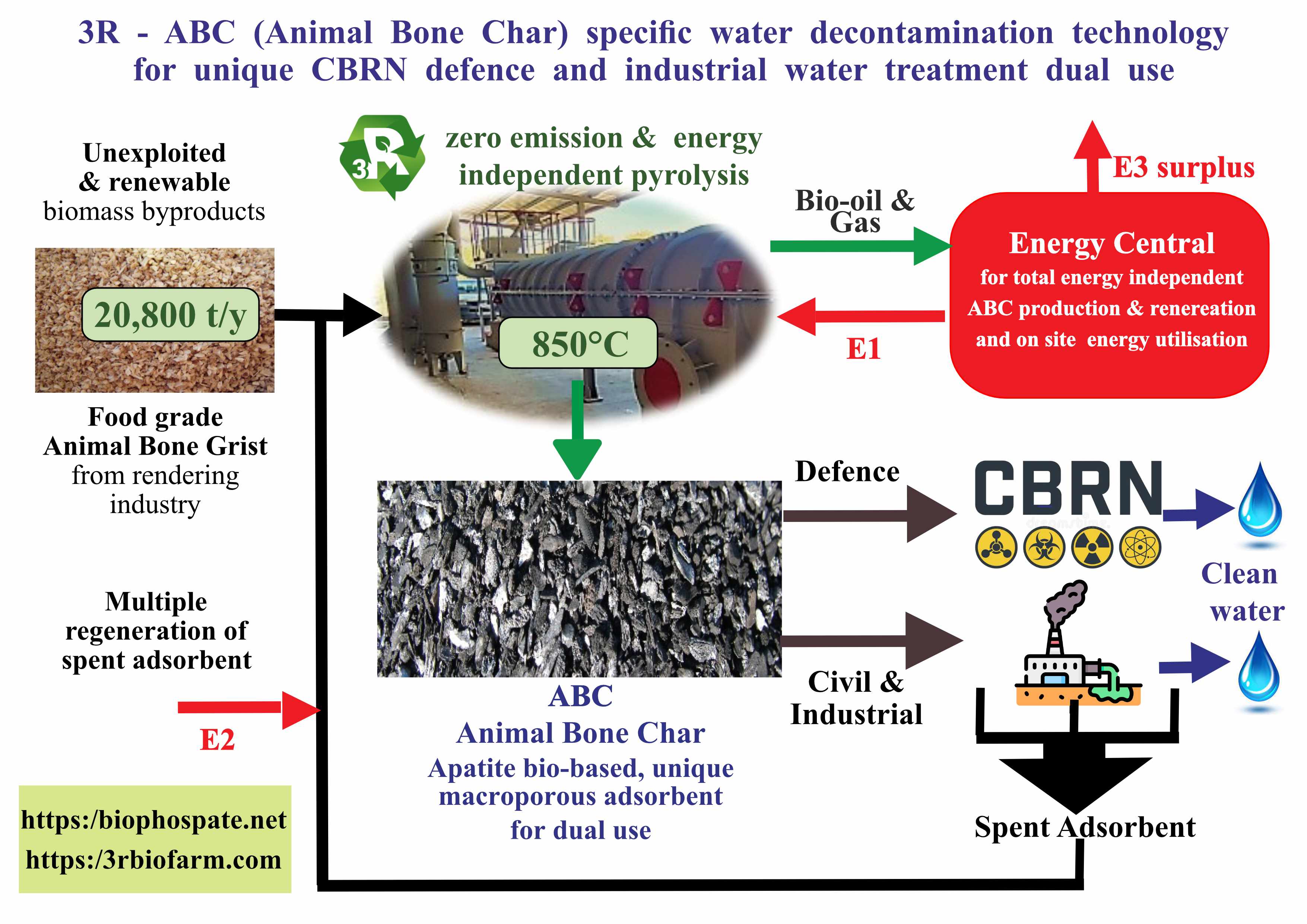

The 3R-engineered ABC Animal Bone Char (BioPhosphate) is a next-generation, bio-based green adsorbent made from food-grade animal bone meal. Through the zero-emission, chemical-free 3R process at 850 °C, it achieves an advanced macroporous structure that makes it significantly more effective than conventional coal- or coconut-based activated carbons.

Outstanding Contaminant Removal

Removes a broad spectrum of pollutants, including heavy metals, fluoride, arsenic, chlorine, pesticides, herbicides, radionuclides (uranium, radium, thorium), and organic colorants.

Excels in the adsorption of large molecules due to its fully macroporous design, unlike traditional micro/mesoporous carbons.

Provides safe, chemical-free purification, preserving essential salts and minerals in drinking water.

Versatile, Industrial-Grade & Defence Use

Widely applicable across industrial water treatment, municipal wastewater purification, food and beverage production, sugar refining, dairy operations, pharmaceuticals, and aquaculture.

Offers nuclear effluent treatment and defence applications, including chemical, biological, radiological hazard mitigation.

Can be regenerated 4–5 times for extended lifecycle and, after use, repurposed as a biofertilizer, supporting a circular economy.

Green by Nature, Better by Design - Why choose green adsorbents?

Zero-emission and sustainable production – no harmful by-products or unnecessary carbon footprint.

Energy-independent – efficient 3R technology based on circular principles.

Renewable & upcycled raw materials – made from animal bone meal.

Circular economy contribution – transforming unexploited biomass into high-value products, reducing waste.

Sustainable end-of-life – can be regenerated, reused.

Chemical-free regeneration, reducing environmental and health risks.

Deliver high adsorption efficiency while being safer, more sustainable, and often more cost-effective long term.

Applications of BioPhosphate Green Adsorbents

BioPhosphate green adsorbents are versatile, high-performance solutions that serve a wide spectrum of industries, combining effective purification with sustainability.

Broad Industry Use:

Water and air purification

Pharmaceuticals

Food processing

Agriculture

Chemical sector

Key Effectiveness Areas:

Industrial wastewater treatment

Environmental remediation

Removal of potentially toxic elements (PTEs) and organic contaminants

Nuclear contamination management – adsorption of radionuclides (e.g., uranium, radium) for safe, chemical-free decontamination

Additional Applications:

Oil and gas processing

Cosmetics and personal care

Military and defence – chemical, biological, and radiological hazard mitigation

Sustainability and Efficiency:

Delivers maximum adsorption efficiency across applications

Provides cost-effective solutions through regeneration and reuse

Can be repurposed after adsorption as a biofertilizer, ensuring long-term environmental value

| PTE (Potential Toxic elements) removal rates of ABC-BioPhosphate from waste water: | |

|---|---|

| Aluminium | >92% |

| Arsenic | > 85% |

| Cadmium | >90% |

| Chromium | >95% |

| Copper | >90% |

| Iron | >99% |

| Lead | >92% |

| Manganese | >99% |

| Phosphorus | >99% |

| Zink | >99% |

| And many other metals... | |

| Reduction parameters: | |

|---|---|

| Chemical Oxygen Demand | >75% |

| Biological Oxygen Demand | >70% |

The benefits of the unique and novel ABC-BioPhosphate adsorbent process/products and the difference versus Activated Carbon materials

| Feature/Capability | ABC-BioPhosphate (green adsorbent) | Conventional Activated Carbon |

|---|---|---|

| Manufacturing Features | ||

| Energy dependence | Produced through an energy-independent 3R process, which can even generate surplus energy. This makes production climate-friendly and cost-efficient. | Requires significant fossil energy input, increasing operational costs and CO₂ emissions. |

| Processing Emission | Zero-emission thermal process, no chemical inputs, no harmful waste. Supports a carbon-negative footprint. | Generates complex emissions and secondary pollutants, often contributing to climate and environmental impacts. |

| Activation method | Thermal activation at >850 °C, entirely chemical-free. Produces a stable macroporous mineral–carbon matrix with high adsorption efficiency. | Chemical or steam activation, often with acids or oxidizers. This can introduce impurities, increase waste streams, and raise environmental and operational risks. |

| Regeneration | Can be regenerated 4–5 times with minimal performance loss. Regeneration is chemical-free, safe, and cost-effective. After adsorbent use, material can be repurposed as a biofertilizer, supporting a circular economy. | Typically 2–5 regeneration cycles. Often requires chemical regeneration, which is costly, less sustainable, and may degrade the material. |

| Sustainability & Environmental Impact | Produced from renewable, upcycled materials (food-grade animal bone meal) via a zero-emission, chemical-free 3R process; supports circular economy and can be reused or repurposed as biofertilizer. Use are carbon-negative and aligned with circular economy principles. | Produced mainly from non-renewable coal or coconut shells, high energy input, limited reuse, generates secondary waste. Can be carbon-neutral to carbon-positive depending on raw material source. Fossil-based feedstocks dominate. |

| Product Features | ||

| Material origin | 100% bio-based, derived from renewable and upcycled biomass (food-grade animal bone meal). | Predominantly fossil-based (coal, lignite) with minor renewable contributions (coconut shell, wood). |

| Material composition | ~92% calcium phosphate mineral + 8% carbon. Mineral content adds extra value for reuse in agriculture. | 100% carbon-based, no added mineral benefits after use. |

| Structure | Fully macroporous (50 µm – 63,000 µm). Optimized for capturing large molecules, heavy metals, radionuclides, and complex contaminants. | Primarily micro- and mesoporous (1–50 µm). Effective for small organic molecules but limited for larger or inorganic contaminants. |

| Primary Function | Specialized adsorbent for removal of PTEs (Potentially Toxic Elements), radionuclides, and macromolecular organic pollutants. | Conventional adsorbent for organic compounds, odour, and taste control. Most effective for micro-pollutants. |

| Target Pollutants | Herbicides, pesticides, PTEs (Cd, Pb, Fe, Mn, Hg, Zn, Cu, Ni, Al), arsenic, fluoride, chlorine, and a wide range of radionuclides (uranium, radium). | Volatile organic compounds (VOCs), chlorine, small organic pollutants. |

| Mineral Retention | Preserves beneficial salts and minerals in water while removing contaminants. | Can remove essential minerals alongside contaminants, lowering water quality. |

| Special Applications | Industrial wastewater, municipal water, sugar refining, pharmaceuticals, aquaculture, defence, nuclear effluents. | Air purification, odour and taste improvement, gas phase adsorption. |

| Best Use Cases | Ideal for PTEs, radionuclides, nutrient recovery, and sustainable water treatment with bio-based circularity. | Best suited for organic contaminant removal, odour, and taste improvements in air and liquid purification. |

| Cost-Effectiveness Over Time | Thanks to its multiple regeneration cycles (4–5 times), long operational lifespan, and ability to be repurposed as a biofertilizer at the end of use, ABC-BioPhosphate significantly reduces replacement frequency and waste disposal costs. Its zero-emission, energy-independent production also helps avoid hidden environmental compliance costs, making it a more sustainable and cost-efficient solution across its full lifecycle. | While the initial purchase cost may be lower, activated carbon typically has shorter regeneration cycles and in many cases is disposed of after a single use. Regeneration, when possible, is energy-intensive and expensive, often offsetting the initial savings. End-of-life disposal generates additional handling costs and provides no added value, resulting in a higher total cost of ownership (TCO) compared to ABC-BioPhosphate. |

In summary:

ABC-BioPhosphate green adsorbents and conventional activated carbons represent two complementary yet distinct purification technologies.

Activated carbon is highly effective for capturing organic compounds, colorants, and volatile pollutants.

ABC-BioPhosphate, on the other hand, is a bio-based green adsorbent designed to target inorganic contaminants such as heavy metals, radionuclides, fluoride, and excess nutrients, while also maintaining high efficiency in complex water and liquid treatment scenarios.

Together, these technologies provide a comprehensive solution for industries ranging from water purification and food processing to environmental remediation and defence applications. They can be applied independently or combined in multi-stage treatment systems, maximizing contaminant removal across a wide spectrum.

By choosing the right adsorbent for the right application, operators gain superior purification performance, long-term cost savings, and stronger environmental compliance, all while advancing sustainability goals.